WhatsApp: +8619037303917

Email: [email protected]

WhatsApp: +8619037303917

Email: [email protected]

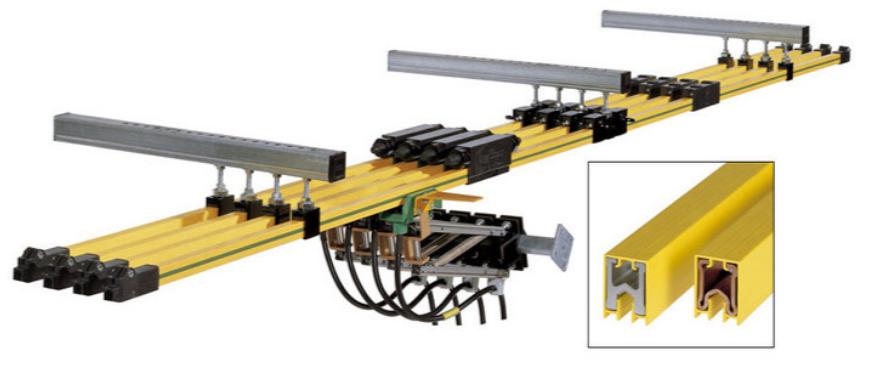

Cranes are essential equipment used extensively in various industries for lifting and transporting heavy loads. However, a crucial component of crane operation often overlooked is the power system, also known as the sliding contact line. This specialized electrical system powers the crane's moving parts and ensures smooth operation. Proper maintenance of the crane power system is vital for extending its lifespan and ensuring safe and efficient performance.

What is a Crane power System?

A crane power system, or sliding contact line, is a method used to supply electrical power to moving or rotating equipment. Unlike fixed power sources, the power system is designed to deliver electricity to parts of the crane that move along a designated path. This system comprises a series of conductive lines and supports that ensure a constant power supply as the crane operates.

Importance of Regular Maintenance

To ensure the crane power system operates optimally, regular maintenance is essential. Here’s a comprehensive guide to maintaining your crane power system:

1. Carbon Brush Inspection

The carbon brushes, which are crucial for transferring electrical current to the moving parts of the crane, should be inspected regularly. If wear on the carbon brushes exceeds 5mm, they need to be checked every 13 months. Pay special attention to the condition of the collector carbon brushes and replace them if necessary. During inspections, look for any looseness or misalignment of the brushes, and address these issues promptly.

2. Check the Spring Tension

The spring tension, which affects the contact pressure between the carbon brushes and the guide rails, should be monitored regularly. This ensures the brushes maintain adequate contact pressure. Inspect the collector system at least once per quarter to check for any loosening of fasteners, displacement, or wear on plastic and moving components. Address any issues immediately to prevent further damage.

3. Inspect Connectors

Connectors, including bolts, welds, and support components, should be inspected at least once a year. Look for any signs of looseness, rust, or displacement. Proper maintenance of these components is crucial to ensure the stability and reliability of the power system.

4. Evaluate Insulation Protection

Regular checks of the insulation protection are necessary to ensure that no components are missing, cracked, or damaged. For fixed-column cranes, check the straightness of the tracks, looking for any misalignment greater than 20mm. Inspect stainless steel "V" grooves for any warping, and ensure there are no foreign objects or conductive dust on the tracks. In cases where insulation resistance is in question, it should meet the requirement of ≥5MΩ between phases.

5. Environmental Considerations

The environment in which the crane operates can significantly impact the power system. Frequent use, high levels of workshop dust, elevated temperatures, and exposure to water, acids, bases, or outdoor elements can cause additional wear and tear. Special attention is needed for fixed-column cranes to address any discrepancies in track alignment, gauge, and inclination due to harsh environmental conditions.

Conclusion

Maintaining the crane power system is essential for ensuring the crane’s optimal performance and longevity. Regular inspections and timely repairs of carbon brushes, spring tension, connectors, insulation, and environmental impacts will help prevent operational issues and enhance safety. By adhering to these maintenance guidelines, you can ensure that your crane operates efficiently and reliably, contributing to the overall productivity and safety of your operations.

Remember, a well-maintained crane not only performs better but also ensures a safer working environment for everyone involved.the efficiency and safety of your material handling processes. Contact us today to learn more about our innovative crane offerings and how we can help take your crane operations to new heights.

TO TOP