Description

The Heavy Duty AGV Transfer Cart is a high-tech automated guided vehicle made to move big and heavy materials in fields like wind energy, transformer, aerospace, the automobile industry, and more.Its features include automated lifting, hydraulic suspension, and collision prevention, ensuring safe, stable, and efficient operations even over rough terrain. It is ideal for use in manufacturing, ports, and hazardous situations, since it improves logistics automation, reduces labor intensity, and increases productivity.

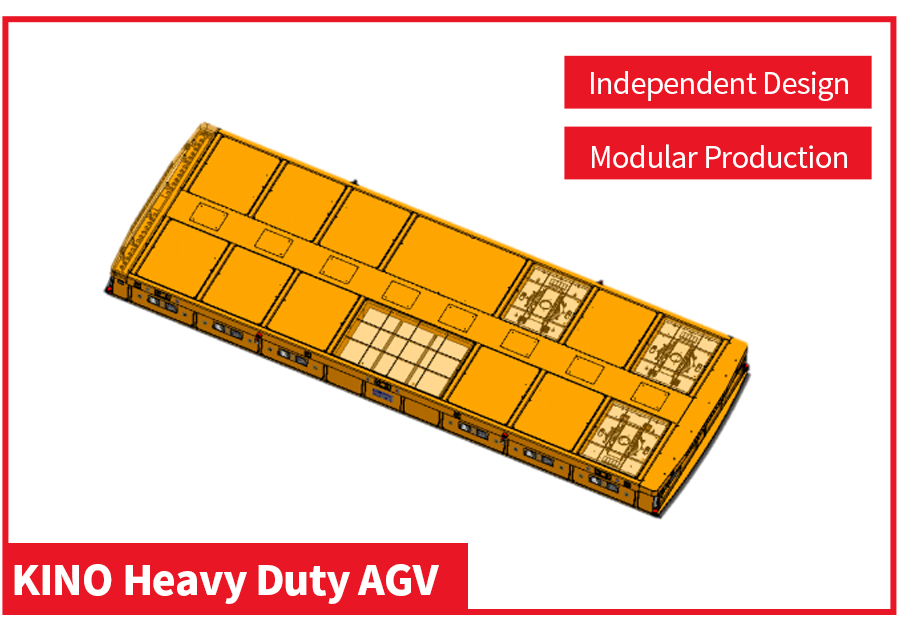

KINO’s heavy-duty AGV trolley for the production, assembly, transportation, and storage of ultra-long, ultra-heavy workpieces has a load capacity of 1-1000T and meets all movement needs for heavy objects and large components. It can be used with the self-developed AGV management system for flexible construction machinery production lines.

Feature

KINO as a leading AGV manufacturer, KINO AGV products have innovations in “eight cutting-edge technologies” and have formed eight major technical systems of heavy-duty AGV, namely servo control system, wireless communication system, synchronous hydraulic system, power monitoring system, safety protection system, intelligent scheduling system, and fault self-diagnosis system, providing “unmanned” system solutions for the transportation and logistics industries of super large and overweight parts.

AGV Technologies Advantage

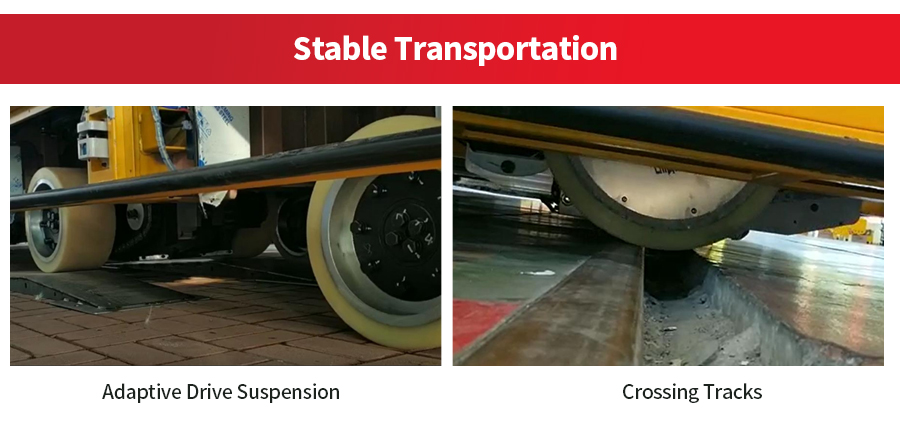

Hydraulic Suspension System:

1. Real-time adjustment of suspension travel to adapt to uneven terrain, slopes, and gaps.

2. Equipped with an inclination sensor to maintain a level platform during operation.

Smooth Operation: Ensures stable start, stop, and movement, preventing product displacement during transport.

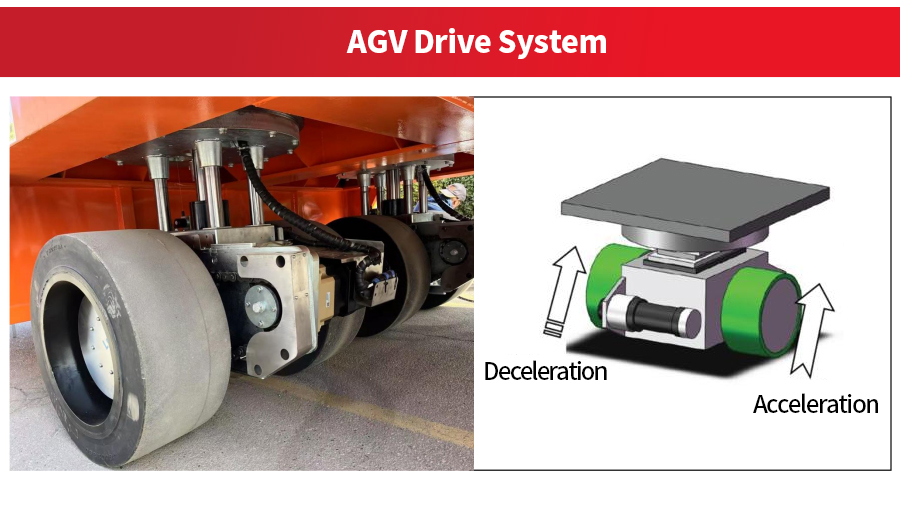

Differential Drive System:

The Differential Drive System enables 360° rotation and omnidirectional movement with high stability in complex environments. It is cost-effective, offers strong load capacity, and minimizes ground damage. Featuring a hydraulic/spring buffer damping system for terrain adaptability and a chain drive design to reduce wear and extend lifespan.

AGVs Specification

| Model |

KNT-20 |

KNT-30 |

KNT-40 |

KNT-70 |

KNT-100 |

KNT-150 |

KNT-150 |

KNT-200 |

KNT-300 |

KNT-400 |

KNT-500 |

KNT-600 |

| Length (mm) (L) |

2800 |

3500 |

4700 |

4100 |

5200 |

6300 |

4800 |

6300 |

7800 |

8850 |

100000 |

125000 |

| Width (mm) (W) |

1600 |

2300 |

2400 |

| Height (mm) (H) |

320 |

360 |

410 |

| Lifting Mode |

Hydraulic Lifting |

| Rated Load (Net Load) (T) |

20 |

30 |

40 |

70 |

100 |

150 |

150 |

200 |

300 |

400 |

500 |

600 |

| Self-Weight (T) |

3 |

4 |

5 |

5 |

6 |

8 |

6 |

9 |

12 |

16 |

20 |

26 |

| Wheel Diameter (mm) |

180 |

250 |

320 |

| Drive Motor Type |

Low Voltage Servo Motor + Independent Servo Controller |

| Battery Type |

Lithium Iron Phosphate Battery |

| Minimum Turning Radius |

0 |

| Full Load Speed on Flat Ground (m/min) |

0-20m/min |

| Full Load Ramp Speed (m/min) |

0-15m/min |

| Lifting Speed Range (mm/s) |

3-5mm/s |

| Walking Precision (mm) |

±2mm |

| Lifting Precision (mm) |

±1mm |

| Applicable Ground |

Concrete, Self-Leveling, Steel Plate, etc. |

| Full Load Climbing Ability |

≤3% |

| Control Method |

Remote Control / Automatic Navigation / Upper Computer Communication Control (Dual Vehicle Linkage Expansion Function) |

| Motion Functions |

Forward, Diagonal, Lateral Movement, Serpentine, Self-Rotation, Variable Radius Turning |

| Weight Measurement Function |

Weight Measurement, Center of Gravity Measurement, Overload Alarm, Off-Center Alarm |

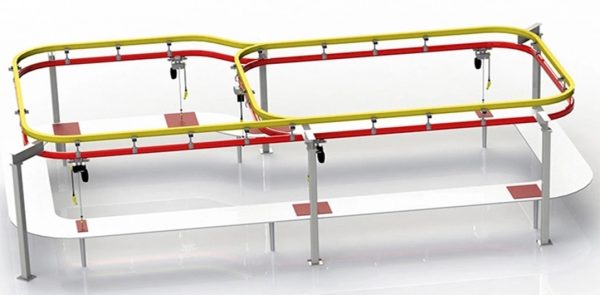

AGV Solution For Transformer Industry

KINO Heavy-Duty AGVs provide tailored solutions for the transformer industry, addressing both component and complete unit transportation needs. By integrating AGVs into production lines, manufacturers can achieve automation, flexibility, and efficiency, meeting the demands of modern transformer production.

Upgrade your production with KINO Heavy Duty AGV Carts. Contact us now!

Other Heavy Duty AGV Projects Display

Transform your production line with KINO Heavy Duty AGV Carts—efficient, reliable, and built for extreme loads. Contact us today!